Beschreibung

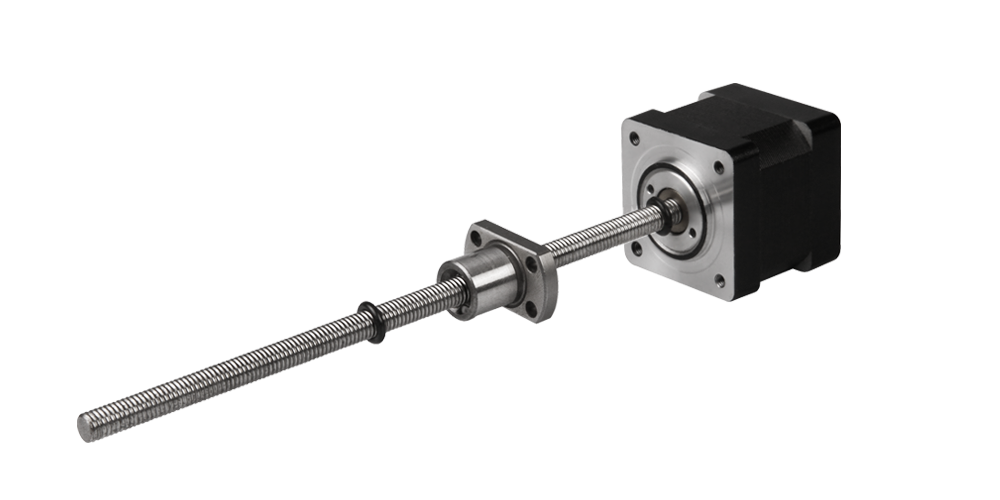

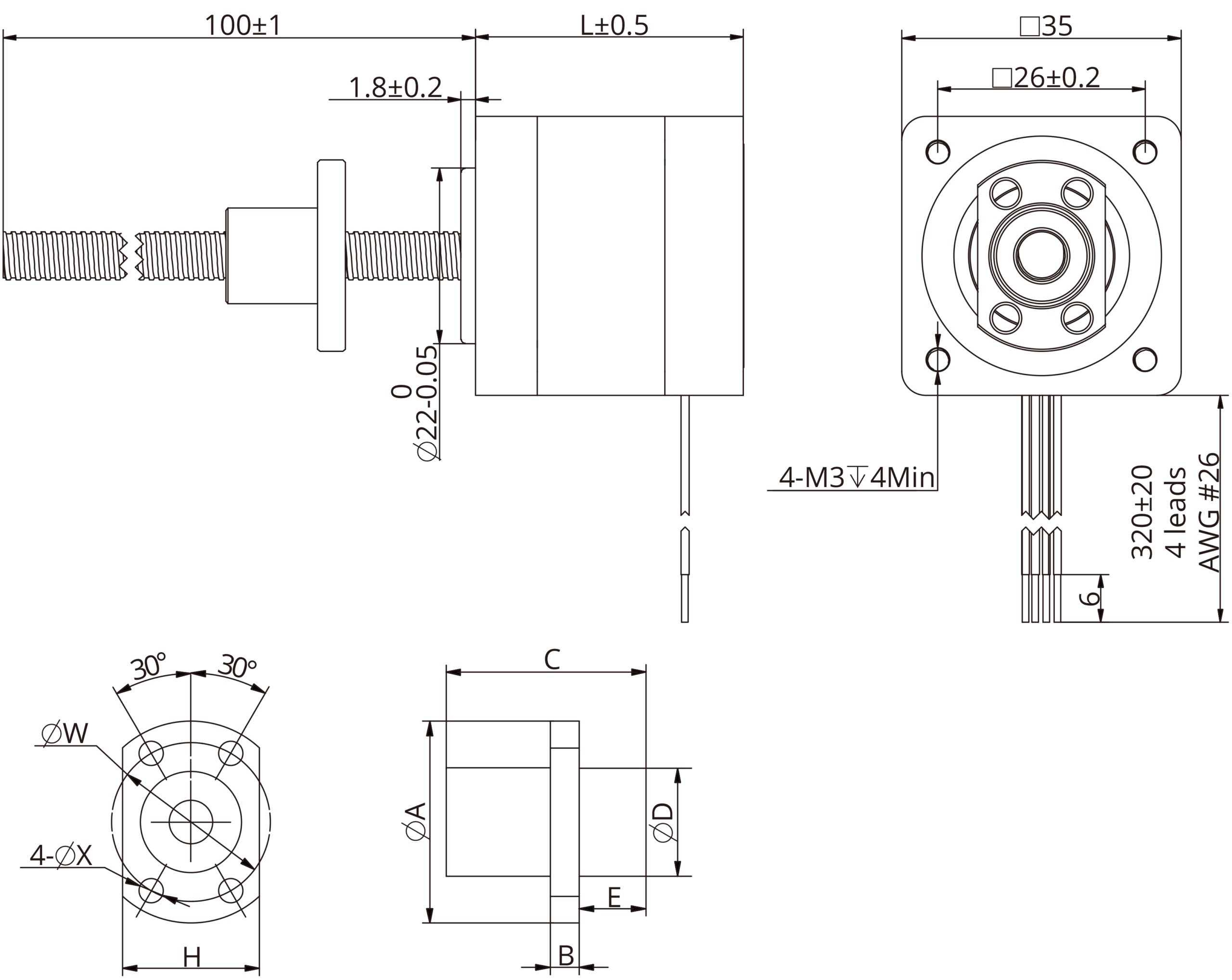

SBSLA – Size 14 [35mm] External Stepper Ball Screw Linear Actuators provide a powerful solution for automated linear motion tasks where precise position control and compact design are critical. Featuring various ball screw types (6mm and 8mm diameters) with multiple pitches (0601–0812) and nut sizes, these actuators are engineered to deliver C7-grade accuracy, excellent rigidity, and long service life.

- Ball Screw Options: Range of screw types (0601, 0602, 0606, 0610, 0801, 0802, 0802.5, 0805, 0808, 0810, 0812) for tailored speed, load, and repeatability.

- Nut Sizes: Multiple nut dimensions (A, B, C, D, H, W, X, E) to fit installation constraints and dynamic/static load requirements up to 2400 N/4100 N (model dependent).

- Material & Surface: Hardened SCM415H shaft nut (HRC58~62), anti-rust oil treatment for durability in demanding environments.

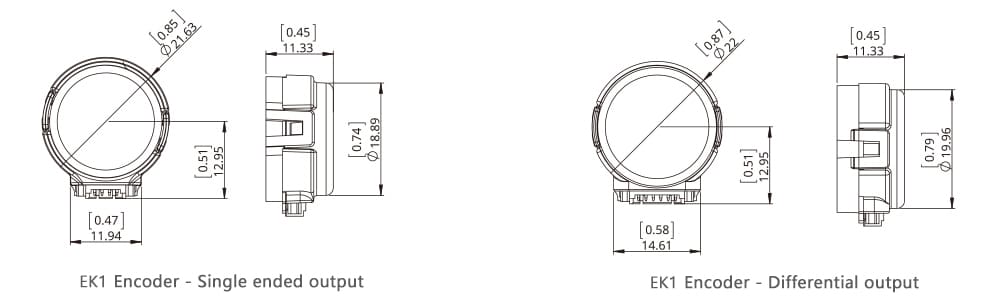

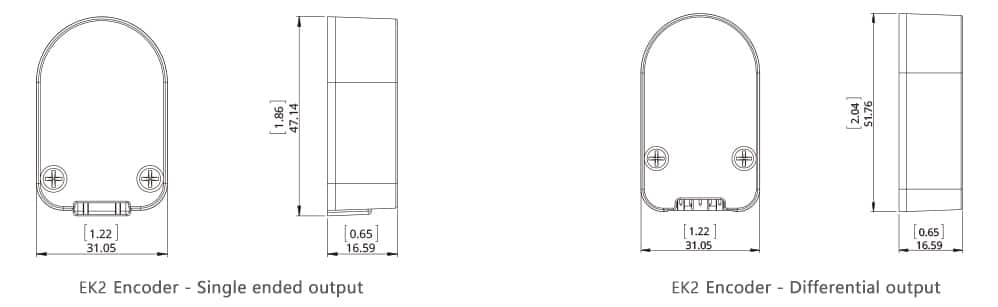

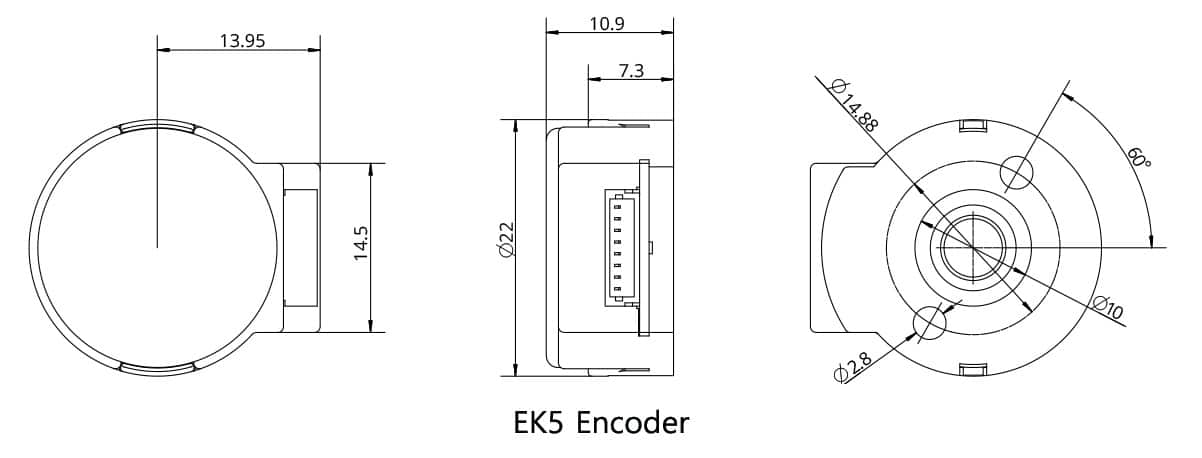

- Customization: Threaded/smooth/custom screw end machining and encoder integration (EK1, EK2, EK5) for position feedback.

- Threading: Right-hand thread, available with various numbers of threads and circuits (single/double).

Applications: Ideal for precision automation, laboratory equipment, semiconductor handling, medical devices, and any compact installation requiring efficient conversion of rotary to linear motion. The range of options ensures adaptability for OEM, system integrators, and engineering projects demanding robust, repeatable performance in a 35mm frame.

External Actuator

External Actuator