Motor Characteristics

| Parameter | Unit | 28ZWWC52-12 | 28ZWWC52-24 | 28ZWWC52-36 | 28ZWWC52-48 | 28ZWWC52-24-2 |

|---|---|---|---|---|---|---|

| Pole Pairs | 1 | 1 | 1 | 1 | 2 | |

| Insulation Resistance | 100 MΩ/500VDC | 100 MΩ/500VDC | 100 MΩ/500VDC | 100 MΩ/500VDC | 100 MΩ/500VDC | |

| Weight | gr | 170 | 170 | 170 | 170 | 170 |

| Rated Voltage | V | 12 | 24 | 36 | 48 | 24 |

| Rated Power | W | 30 | 34 | 35 | 35 | 37 |

| Rated Torque | mNm | 32 | 32 | 32 | 34 | 50 |

| Rated Speed | RPM | 6970 | 8430 | 8370 | 8340 | 7000 |

| Rated Current | A | 3.13 | 1.69 | 1.17 | 0.86 | 2.00 |

| No Load Speed | RPM | 9270 | 9680 | 9500 | 9400 | 8500 |

| No Load Current | A | 0.2 | 0.11 | 0.084 | 0.061 | 0.12 |

| Motor Efficiency | % | 80 | 84 | 83 | 85 | 81.5 |

| Phase Resistance | Ω | 0.52 | 1.7 | 4.3 | 6.6 | 1.6 |

| Noise (Ambient noise 20db, test distance 1M) | dB | <50 | <50 | <50 | <50 | <50 |

| Case – Environmental thermal resistance (no load) | K/W | 0.67 | 0.69 | 0.73 | 0.64 | 0.70 |

| Motor Thermal Time Constant(No Load) | S | 1200 | 1200 | 1080 | 1100 | 880 |

| Ambient Temperature | °C | 23 | 24 | 27 | 25 | 21.2 |

| Maximum Winding Temperature(No Load) | °C | 43.2 | 47.3 | 52.5 | 47.4 | 46.7 |

| Torque Constant | mN·m/A | 10.24 | 18.97 | 27.32 | 39.63 | 25 |

| Back-EMF Constant /Peak Value | V/Krpm | 1.52 | 2.81 | 4.04 | 5.87 | 3.70 |

| Back-EMF Constant /Effective Value | V/Krpm | 1.07 | 1.99 | 2.86 | 4.15 | 2.62 |

| Peak Torque | mNm | 236.31 | 267.87 | 228.72 | 288.25 | 375 |

| Peak Current | A | 23 | 14 | 8 | 7 | 15 |

| Phase Inductance | mH | 0.0495 | 0.178 | 0.42 | 0.77 | 0.13 |

| Inertia Moment | g·cm² | 10.2 | 10.2 | 10.2 | 10.2 | 10.2 |

| Mechanical Time Constant | ms | 5.06 | 4.82 | 5.88 | 4.29 | 2.61 |

| End Cover | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | |

| Bearing | Deep Groove Ball Bearing | Deep Groove Ball Bearing | Deep Groove Ball Bearing | Deep Groove Ball Bearing | Deep Groove Ball Bearing | |

| Magnet | Sinter NdFeB | Sinter NdFeB | Sinter NdFeB | Sinter NdFeB | Sinter NdFeB | |

| Shaft | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | |

| Winding Connection | Star shape | Star shape | Star shape | Star shape | Star shape | |

| Insulation Class | B | B | B | B | B | |

| Duty Type | S2 | S2 | S2 | S2 | S1 | |

| Feedback Method | Hall Sensors | Hall Sensors | Hall Sensors | Hall Sensors | Hall Sensors | |

| Commutation Angle | 120° | 120° | 120° | 120° | 120° | |

| Insulation Strength (Withstand Voltage) | 500VAC/1KHz/1mA/1s | 500VAC/1KHz/1mA/1s | 500VAC/1KHz/1mA/1s | 500VAC/1KHz/1mA/1s | 500VAC/1KHz/1mA/1s |

Technical specifications are for guidance only, as the individual drives and motors are configured for specific applications. Subject to technical and visual changes.

SLBLDC – Size 28mm

PDF Downloads

| Parameter | Unit | 28ZWWC52-12 |

|---|---|---|

| Pole Pairs | 1 | |

| Insulation Resistance | 100 MΩ/500VDC | |

| Weight | gr | 170 |

| Rated Voltage | V | 12 |

| Rated Power | W | 30 |

| Rated Torque | mNm | 32 |

| Rated Speed | RPM | 6970 |

| Rated Current | A | 3.13 |

| No Load Speed | RPM | 9270 |

| No Load Current | A | 0.2 |

| Motor Efficiency | % | 80 |

| Phase Resistance | Ω | 0.52 |

| Noise (Ambient noise 20db, test distance 1M) | dB | <50 |

| Case – Environmental thermal resistance (no load) | K/W | 0.67 |

| Motor Thermal Time Constant(No Load) | S | 1200 |

| Ambient Temperature | °C | 23 |

| Maximum Winding Temperature(No Load) | °C | 43.2 |

| Torque Constant | mN·m/A | 10.24 |

| Back-EMF Constant /Peak Value | V/Krpm | 1.52 |

| Back-EMF Constant /Effective Value | V/Krpm | 1.07 |

| Peak Torque | mNm | 236.31 |

| Peak Current | A | 23 |

| Phase Inductance | mH | 0.0495 |

| Inertia Moment | g·cm² | 10.2 |

| Mechanical Time Constant | ms | 5.06 |

| End Cover | Stainless Steel | |

| Bearing | Deep Groove Ball Bearing | |

| Magnet | Sinter NdFeB | |

| Shaft | Carbon Steel | |

| Winding Connection | Star shape | |

| Insulation Class | B | |

| Duty Type | S2 | |

| Feedback Method | Hall Sensors | |

| Commutation Angle | 120° | |

| Insulation Strength (Withstand Voltage) | 500VAC/1KHz/1mA/1s |

Technical specifications are for guidance only, as the individual drives and motors are configured for specific applications. Subject to technical and visual changes.

PDF Downloads

| Parameter | Unit | 28ZWWC52-24 |

|---|---|---|

| Pole Pairs | 1 | |

| Insulation Resistance | 100 MΩ/500VDC | |

| Weight | gr | 170 |

| Rated Voltage | V | 24 |

| Rated Power | W | 34 |

| Rated Torque | mNm | 32 |

| Rated Speed | RPM | 8430 |

| Rated Current | A | 1.69 |

| No Load Speed | RPM | 9680 |

| No Load Current | A | 0.11 |

| Motor Efficiency | % | 84 |

| Phase Resistance | Ω | 1.7 |

| Noise (Ambient noise 20db, test distance 1M) | dB | <50 |

| Case – Environmental thermal resistance (no load) | K/W | 0.69 |

| Motor Thermal Time Constant(No Load) | S | 1200 |

| Ambient Temperature | °C | 24 |

| Maximum Winding Temperature(No Load) | °C | 47.3 |

| Torque Constant | mN·m/A | 18.97 |

| Back-EMF Constant /Peak Value | V/Krpm | 2.81 |

| Back-EMF Constant /Effective Value | V/Krpm | 1.99 |

| Peak Torque | mNm | 267.87 |

| Peak Current | A | 14 |

| Phase Inductance | mH | 0.178 |

| Inertia Moment | g·cm² | 10.2 |

| Mechanical Time Constant | ms | 4.82 |

| End Cover | Stainless Steel | |

| Bearing | Deep Groove Ball Bearing | |

| Magnet | Sinter NdFeB | |

| Shaft | Carbon Steel | |

| Winding Connection | Star shape | |

| Insulation Class | B | |

| Duty Type | S2 | |

| Feedback Method | Hall Sensors | |

| Commutation Angle | 120° | |

| Insulation Strength (Withstand Voltage) | 500VAC/1KHz/1mA/1s |

Technical specifications are for guidance only, as the individual drives and motors are configured for specific applications. Subject to technical and visual changes.

SLBLDC – Size 28mm

PDF Downloads

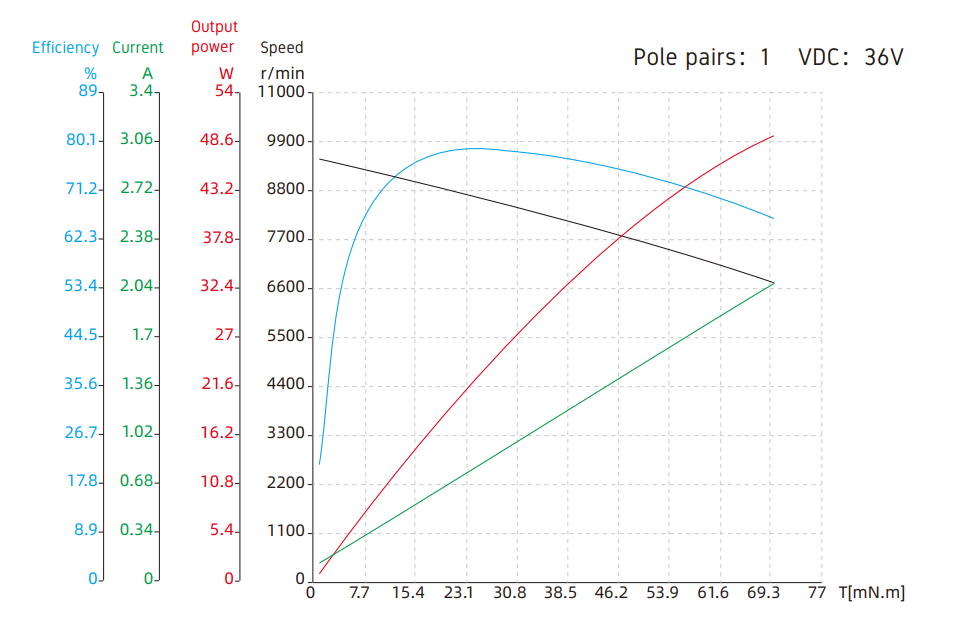

| Parameter | Unit | 28ZWWC52-36 |

|---|---|---|

| Pole Pairs | 1 | |

| Insulation Resistance | 100 MΩ/500VDC | |

| Weight | gr | 170 |

| Rated Voltage | V | 36 |

| Rated Power | W | 35 |

| Rated Torque | mNm | 32 |

| Rated Speed | RPM | 8370 |

| Rated Current | A | 1.17 |

| No Load Speed | RPM | 9500 |

| No Load Current | A | 0.084 |

| Motor Efficiency | % | 83 |

| Phase Resistance | Ω | 4.3 |

| Noise (Ambient noise 20db, test distance 1M) | dB | <50 |

| Case – Environmental thermal resistance (no load) | K/W | 0.73 |

| Motor Thermal Time Constant(No Load) | S | 1080 |

| Ambient Temperature | °C | 27 |

| Maximum Winding Temperature(No Load) | °C | 52.5 |

| Torque Constant | mN·m/A | 27.32 |

| Back-EMF Constant /Peak Value | V/Krpm | 4.04 |

| Back-EMF Constant /Effective Value | V/Krpm | 2.86 |

| Peak Torque | mNm | 228.72 |

| Peak Current | A | 8 |

| Phase Inductance | mH | 0.42 |

| Inertia Moment | g·cm² | 10.2 |

| Mechanical Time Constant | ms | 5.88 |

| End Cover | Stainless Steel | |

| Bearing | Deep Groove Ball Bearing | |

| Magnet | Sinter NdFeB | |

| Shaft | Carbon Steel | |

| Winding Connection | Star shape | |

| Insulation Class | B | |

| Duty Type | S2 | |

| Feedback Method | Hall Sensors | |

| Commutation Angle | 120° | |

| Insulation Strength (Withstand Voltage) | 500VAC/1KHz/1mA/1s |

Technical specifications are for guidance only, as the individual drives and motors are configured for specific applications. Subject to technical and visual changes.

SLBLDC – Size 28mm

PDF Downloads

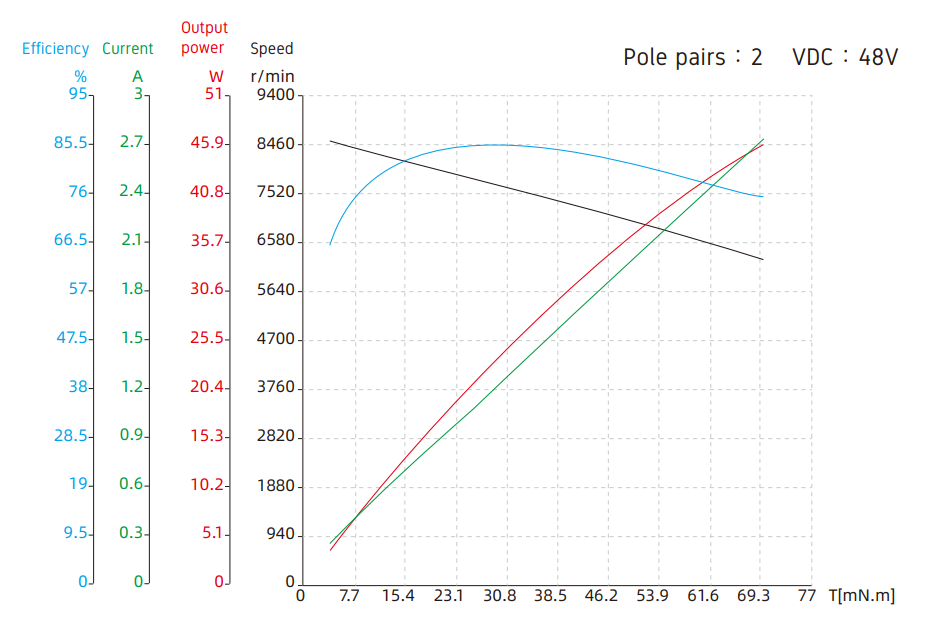

| Parameter | Unit | 28ZWWC52-48 |

|---|---|---|

| Pole Pairs | 1 | |

| Insulation Resistance | 100 MΩ/500VDC | |

| Weight | gr | 170 |

| Rated Voltage | V | 48 |

| Rated Power | W | 35 |

| Rated Torque | mNm | 34 |

| Rated Speed | RPM | 8340 |

| Rated Current | A | 0.86 |

| No Load Speed | RPM | 9400 |

| No Load Current | A | 0.061 |

| Motor Efficiency | % | 85 |

| Phase Resistance | Ω | 6.6 |

| Noise (Ambient noise 20db, test distance 1M) | dB | <50 |

| Case – Environmental thermal resistance (no load) | K/W | 0.64 |

| Motor Thermal Time Constant(No Load) | S | 1100 |

| Ambient Temperature | °C | 25 |

| Maximum Winding Temperature(No Load) | °C | 47.4 |

| Torque Constant | mN·m/A | 39.63 |

| Back-EMF Constant /Peak Value | V/Krpm | 5.87 |

| Back-EMF Constant /Effective Value | V/Krpm | 4.15 |

| Peak Torque | mNm | 288.25 |

| Peak Current | A | 7 |

| Phase Inductance | mH | 0.77 |

| Inertia Moment | g·cm² | 10.2 |

| Mechanical Time Constant | ms | 4.29 |

| End Cover | Stainless Steel | |

| Bearing | Deep Groove Ball Bearing | |

| Magnet | Sinter NdFeB | |

| Shaft | Carbon Steel | |

| Winding Connection | Star shape | |

| Insulation Class | B | |

| Duty Type | S2 | |

| Feedback Method | Hall Sensors | |

| Commutation Angle | 120° | |

| Insulation Strength (Withstand Voltage) | 500VAC/1KHz/1mA/1s |

Technical specifications are for guidance only, as the individual drives and motors are configured for specific applications. Subject to technical and visual changes.

SLBLDC – Size 28mm

PDF Downloads

| Parameter | Unit | 28ZWWC52-24-2 |

|---|---|---|

| Pole Pairs | 2 | |

| Insulation Resistance | 100 MΩ/500VDC | |

| Weight | gr | 170 |

| Rated Voltage | V | 24 |

| Rated Power | W | 37 |

| Rated Torque | mNm | 50 |

| Rated Speed | RPM | 7000 |

| Rated Current | A | 2.00 |

| No Load Speed | RPM | 8500 |

| No Load Current | A | 0.12 |

| Motor Efficiency | % | 81.5 |

| Phase Resistance | Ω | 1.6 |

| Noise (Ambient noise 20db, test distance 1M) | dB | <50 |

| Case – Environmental thermal resistance (no load) | K/W | 0.70 |

| Motor Thermal Time Constant(No Load) | S | 880 |

| Ambient Temperature | °C | 21.2 |

| Maximum Winding Temperature(No Load) | °C | 46.7 |

| Torque Constant | mN·m/A | 25 |

| Back-EMF Constant /Peak Value | V/Krpm | 3.70 |

| Back-EMF Constant /Effective Value | V/Krpm | 2.62 |

| Peak Torque | mNm | 375 |

| Peak Current | A | 15 |

| Phase Inductance | mH | 0.13 |

| Inertia Moment | g·cm² | 10.2 |

| Mechanical Time Constant | ms | 2.61 |

| End Cover | Stainless Steel | |

| Bearing | Deep Groove Ball Bearing | |

| Magnet | Sinter NdFeB | |

| Shaft | Carbon Steel | |

| Winding Connection | Star shape | |

| Insulation Class | B | |

| Duty Type | S1 | |

| Feedback Method | Hall Sensors | |

| Commutation Angle | 120° | |

| Insulation Strength (Withstand Voltage) | 500VAC/1KHz/1mA/1s |

Technical specifications are for guidance only, as the individual drives and motors are configured for specific applications. Subject to technical and visual changes.